Materials for building your own trailer hitch cargo carrier should cost about 75 percent of buying one ready-made, so you will be trading time for savings. Having the satisfaction of building it counts, and you can do some customizing as you go. The basic materials are available on the Internet, and construction does not require welding equipment. The design will fit a two-inch hitch receiver and lock pin. Carrying capacity is around 300 pounds.

Items you will need

2 pieces 1/8-inch 2-by-3 inch angle iron, 60 inches long

4 pieces 1/8-inch 2-by-3 inch angle iron, 24 inches long

1 piece 2-inch square, 1/4-inch thick wall steel tubing, 24 inches long

2 pieces 5/8-inch wide, 3/16-inch thick steel bar, 36 inches long

Drill press

Carbide-tipped drill bit assortment

32 stainless 3/16 bolts, 3/4-inch-long, with nylock nuts

8 stainless 3/16 bolts, 3 inches long, with nylock nuts

8 stainless washers

1 sheet of steel diamond mesh, 60-by-20 inches

Brake cleaner

Light gray steel primer

Steel paint

Phillips screwdriver

Wrench set

Steel-cutting chop saw

Construction square

Use the miter saw to cut all the 24-inch angle iron down to 20 inches.

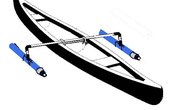

Lay down the 60-inch angle in parallel about 20 inches apart, with flats pointing toward each other. Lay the 20-inch end pieces with their ends inside and at a right-angle to both long pieces so they form a rectangle. Lay remaining 20-inch pieces the same way, 20 inches from each end of the rectangle. Pencil-mark all positions.

Use the drill press to make holes through both layers of angle iron. Make holes 1-1/16 larger than the short bolts at all corners and other joints. Use a construction square to set right angles and clamp angle iron in place on the press table. Drill holes in a 1-inch square pattern at the center of each 2-inch overlap.

Temporarily bolt the rectangle together. Attach the remaining 20-inch angle iron 20 inches in from the ends upside-down from underneath, so mesh will lie flat inside the frame.

Center the square tube between the rectangle ends, protruding 4 inches at the hitch side, flush with the other side. Clamp all parts onto the drill press table and drill a 4-bolt-hole in a square pattern through the angle iron and the tube on both sides.

Temporarily bolt the tube to the frame with long bolts. Turn the assembly upside-down. Center a flat bar over the tube at each long side of the rectangle. Bend the bar down on both ends to touch the angle iron, and lip-bend the bar back 2 inches from the ends so that it will bolt down flat.

Drive two holes through each bar end and through angle iron, and two through the bar, tube and angle iron in the center. Turn assembly right-side up and trim mesh to fit inside the rectangle.

Slide protruding tube into a hitch receiver and make marks for drilling the lock pin hole. Disassemble all parts. Press-drill holes through the tube for a lock pin.

Soak and clean all steel with Brakleen. Spray on four coats of primer, allowing dry time between applications. Spray on two coats of paint.

Reassemble all parts. Leave out one bolt at each angle joint. Lay mesh into the rectangle. Insert remaining bolts with stainless washers through the mesh. Tighten all bolts. Paint entire assembly.

References

Writer Bio

Jan Benschop started writing professionally in 1979. His corporate technical writing clients included Nortel, Alcatel and Glaxo. Also the author of several short stories, Benschop holds a Bachelor of Science in English from Campbell University. He built loudspeakers for more than a decade and has several international patents pending in the field.