Introduction

Soldering gun. Creative Commons photo by ""Bgrimer""

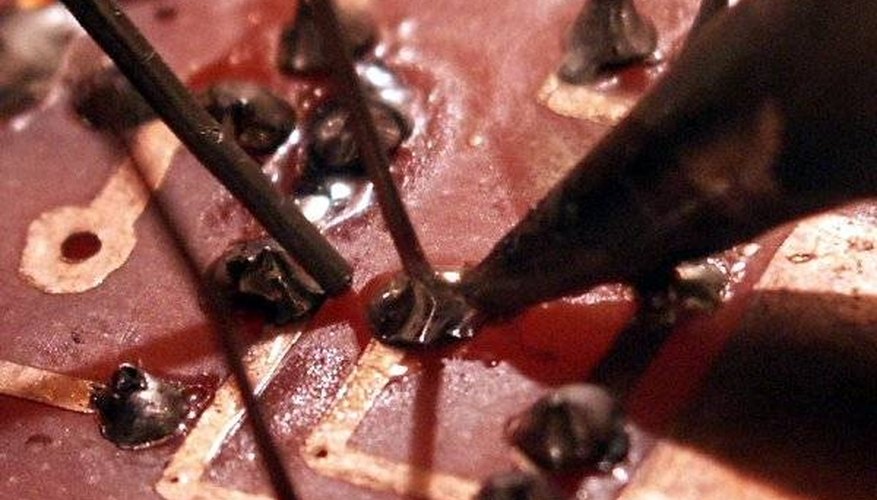

A soldering gun is a tool designed to supply the necessary heat required in melting and applying solder. Solder is used as a conductive material in electrical connections, and for low strength metal-to-metal fastening such as light duty metal work.

Soldering Guns vs. Soldering Irons

Soldering gun. Creative Commons photo by ""Bgrimer""

Although soldering guns and soldering irons perform the same basic function, there are some differences between the two tools. Soldering guns are designed for intermittent use, whereas soldering irons are meant to remain hot for longer periods of time. A soldering gun does not use fine windings of resistance wire to generate heat, as a soldering iron does. Instead it uses a transformer to convert 110 AC to a lower voltage. That voltage is routed through the copper soldering tip, which is heated by the current flowing through it. Soldering guns have a trigger that must be depressed to begin the heating process. The low voltage, high amperage current flows through the tip, which generally reaches operating temperature within 15 seconds. Most soldering guns include a small light that comes on when the trigger is depressed; this permits greater visibility of the material being soldered. Soldering irons, on the other hand, are typically "on" as soon as they're plugged in and remain so until unplugged.

Soldering

Soldering gun. Creative Commons photo by ""Bgrimer""

Once the soldering gun has reached operating temperature, solder is applied to the tip in a process known as "tinning." This serves the dual purpose of cleaning the tip of old solder that would interfere with soldering, and melting new solder to be applied to the work. The tinned tip is then applied momentarily to both pieces of material that will be soldered, and additional solder is applied from the roll of solder to the work rather than to the soldering gun's tip.

Proper soldering temperature is reached when the solder flows freely when touched to the work. A good solder joint will be shiny and have flat edges.

Solder tends to move towards the source of heat, so when soldering two pieces of flat metal together, the solder will tend to flow towards the tip. Capillary action will draw the solder into the joint if the correct temperature has been achieved.

Caution!

Once a solder connection is established, don't move the work until the solder has solidified. This usually takes no longer than 30 seconds, and often much less time. Take care when handling the soldering gun after using it, as the tip will remain hot to the touch for quite some time and can ignite combustible materials. Although solder is not suitable for certain metals, such as aluminum and nickel, other materials, such as zinc-plated sheet metal, copper and silver, can be soldered quite easily.