Creating a center console for your boat, whether as a replacement for a console that's been damaged or one that's simply worn out, is like building a box. The difference is that one side and the top can be removed for access to the interior, and the top slants toward the rear of the boat for drainage of any water that overwhelms the sides of the boat and splashes onto the console. Caulked seams and a fiberglass cover complete the project. Begin by drawing up a plan, including the dimensions of the new center console.

Items you will need

Measuring tape

Circular saw

Marine plywood

Rright-angle braces

Drill

5/8-inch tapered drill bit

No. 5 wood screws, 1.25 inches long

Marine epoxy resin

Fiberglass mat

Gloves

Safety glasses

Putty knife

320-grit sandpaper

Step 1

Measure and cut the top panel of the console from 3/4-inch marine plywood. Measure and cut the forward panel of the console from a sheet of 3/4-inch marine plywood. Ensure that the height and width of the forward panel equal that expressed by the console plans. Measure and cut the rear panel of the console from a sheet of 3/4-inch marine plywood. The rear panel's width should equal the width the front panel, but the rear panel height is 3 inches less than that of the front panel.

Step 2

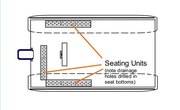

Measure and cut two equal-sized pieces from a sheet of 3/4-inch marine plywood to form the side panels of the console. Ensure that the panels' width be that of the depth of the planned center console. Plan for the forward edge of each piece to be equal to the planned height of the console, that is, equal to the height of the forward panel. The rear edge of the panel is 3 inches shorter than the height of the forward panel.

Step 3

Assemble the console by attaching five right-angle braces on each side of the front panel -- use the screws supplied with the braces -- each 3/4 inch from the edge of the sides of the panel. Attach the sides to the right-angle braces so the top and bottom of each side panel is even with the top edge of the front panel and the face of each side panel is even with the outer side edge of the front panel.

Step 4

Align the left edge of rear panel with the rear edge of the left side panel. Drill four holes with a 5/8-inch tapered drill bit through each side of the rear panel into the edges of the side panels. Make the holes should be 1.25 inches deep. Repeat this operation for the right side of the rear panel. Secure the rear panel to the side panels with No. 5 wood screws, each 1.25 inches long.

Step 5

Stand the console upright and set the top panel, the dash board, in place on the angled end of the console. Keep the dashboard in place by duct taping the front edge of the dash to the front panel of the console. Drill four holes, each 1.25 inches deep, on each side of the dashboard, into the edges of the console with a 5/8-inch tapered drill bit. Secure the dashboard to the edges of the panels of the console with No. 5 wood screws, each 1.25 inches long.

Step 6

Mount the completed center console on the boat, and remove the rear console. Caulk all seams of the front and side panels of the console with marine silicone caulk. Remove the rear panel. Drill and cut all openings for controls and instruments.

Step 7

Apply marine epoxy resin to all exterior surfaces of the pedestal. Lay sheets of fiberglass mat on the resin, and use a putty knife to work the fiberglass mat into the resin. Allow the fiberglass to cure for one hour, then apply more resin and more fiberglass mat, sanding between each layer with 320-grit sand paper, until you have applied three layers of fiberglass. Sand the finished surface with 320-grit sandpaper.

Writer Bio

Will Charpentier is a writer who specializes in boating and maritime subjects. A retired ship captain, Charpentier holds a doctorate in applied ocean science and engineering. He is also a certified marine technician and the author of a popular text on writing local history.